- HONGSHENG

- CHINA

HS-600A can realize a series of actions such as 9 buckles drawing-in, automatic strap cutting, 8 buckles drawing-in, folding knot, 8 buckles returning, material collecting, etc.

It has switchable automatic and manual mode, and has a number of fault alarm automatic shutdown functions;

Functions such as thread breaking detection, material joint detection、Shoulder strap sticking detection and so on.

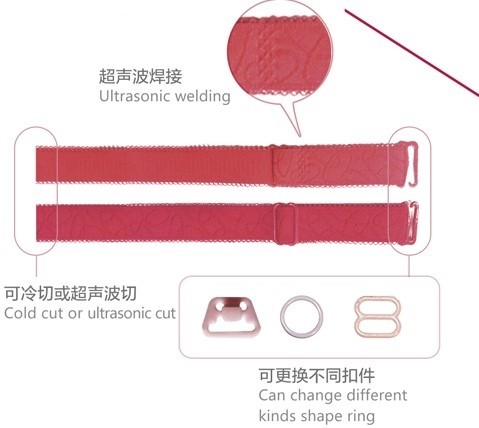

The machine can adjust the mould flexibly according to the specific requirements of customers and produce shoulder straps with different widths.

Moulds of different buckle type can be selected to produce 8 + 0 buckle, 8 + 8 buckle, 8 + 9 buckle, 8 + Mommy buckle and so on. Various non-standard buckle moulds can also be developed for customers' requirements.

Production mode of machine can be adjusted to produce single-8 buckles at high speed.

Ultrasonic knife can be selected for ultrasonic welding.

HS-600U Full Automatic Ultrasonic Shoulder Strap Welding Machine

HS-600U Full Automatic Ultrasonic Shoulder Strap Welding Machine

Hongsheng HS-600A, Automatic shoulder strap welding machine is an intelligent and automatic production equipment. This machine runs efficiently and stably.

The machine solves the problems of the traditional handmade, such as shoulder strap deformation, different length, low production efficiency and high labor cost

HS-600A reduces the cost of personnel, equipment investment and loss, and greatly improves the production capacity and efficiency of shoulder strap production.

This machine adopts micro-computer control and a full set of SMC cylinders linkage. Equipped with JUKI1900 knotting sewing machine and stepping motor, it can effectively reduce about 50% of the power consumption. It runs fast, has low noise, strong penetrating power, stable and reliable performance, and effectively prolongs the service life of the machine.

One worker can operate multiple automatic shoulder strap machine. It only takes 5-6 seconds to produce a shoulder strap. Calculating according to the workload of 10 hours of each machine per day, one Hongsheng HS-600A equipment can produce 6000-7200 shoulder straps;Suppose that one person operates five sets, each person can produce 30,000-36,000 shoulder straps per day.